Industrial Flooring

.

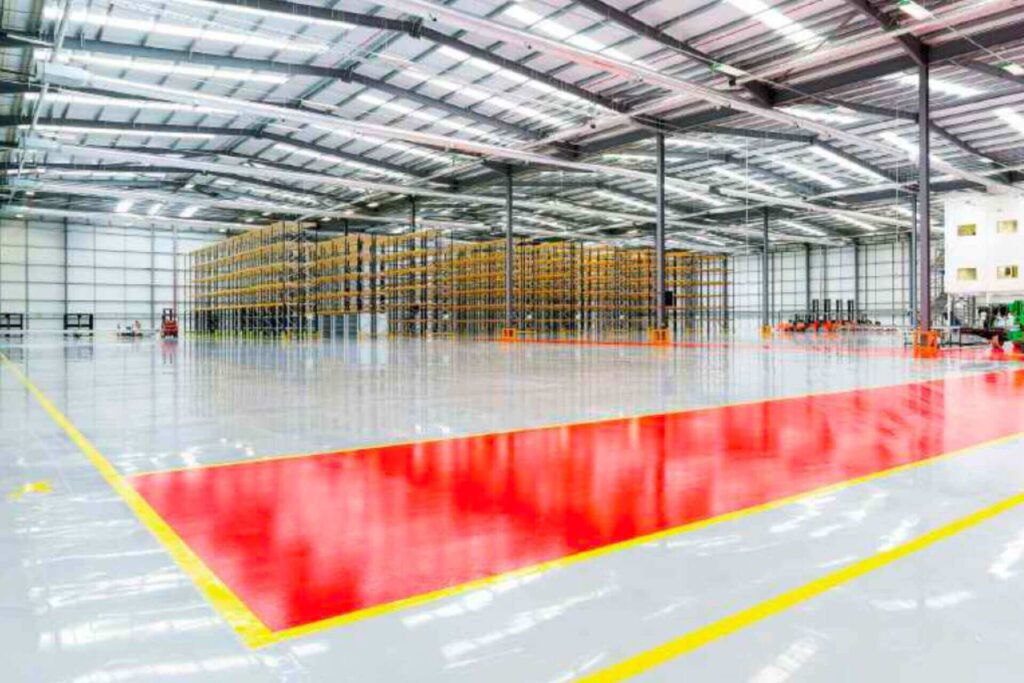

We Focus To Make Your Industrial Flooring functional

Industrial spaces require specialized infrastructure to function seamlessly and maintain a high level of safety. Industrial flooring not only plays a significant role in the overall aesthetics of the workspace but also impacts the efficiency and safety of operations.

Industrial flooring serves as the foundation for a wide range of activities in manufacturing plants, warehouses, distribution centers, and other industrial settings.

Unlike commercial or residential flooring, industrial floors must withstand heavy machinery, foot traffic, chemical spills, impacts, and abrasion on a daily basis. They need to be durable, easy to maintain, and resistant to various environmental factors.

5 Key Factors to Consider in Industrial Flooring

- Durability and Strength:

Heavy duty flooring are made of flooring materials that are designed to withstand significant wear and tear, heavy loads of equipment, high traffic, constant movement and impacts without deteriorating quickly. These types of flooring are commonly used in commercial and industrial settings where durability and longevity are crucial.

When choosing heavy duty flooring, factors such as the specific environment, expected types of loads, and the presence of chemicals or moisture should be considered. Proper installation and maintenance are crucial to ensuring the longevity and effectiveness of heavy duty flooring.

- Chemical Resistance:

Many industrial processes involve the use of chemicals and liquids that can damage standard flooring materials. Chemical resistant flooring is designed to withstand exposure to various chemicals, acids, solvents, and other corrosive substances without deteriorating or being damaged.

This type of flooring is essential in environments where chemicals are regularly used, such as laboratories, manufacturing plants, chemical processing facilities, industrial kitchens, and more.

- Safety:

Slips, trips, and falls are common causes of workplace accidents. Industrial flooring should offer excellent traction, even in wet conditions, to reduce the risk of accidents.

Anti-slip flooring, also known as slip-resistant or non-slip flooring, is designed to provide traction and reduce the risk of slips, trips, and falls, especially in areas where floors can become slippery due to moisture, oil, grease, or other contaminants.

This type of flooring is essential in environments where safety is a top priority, such as commercial kitchens, bathrooms, swimming pool areas, outdoor spaces & industrial settings like auto-workshop, chemical plants & food & beverage processing factories.

- Easy Maintenance:

In busy industrial settings, downtime for maintenance needs to be minimized. A low-maintenance flooring solution can significantly impact productivity by reducing the time spent on cleaning and repairs.

Self-leveling industrial flooring, also known as self-leveling epoxy flooring or industrial self-leveling concrete, is a specialized type of flooring commonly used in industrial and commercial settings.

It offers durability, chemical resistance, and a smooth, level surface that can withstand heavy machinery, foot traffic, and other stresses.

This type of flooring is often chosen for its ability to create a seamless, low-maintenance, and high-performance surface in environments where functionality is a top priority.

- Aesthetics:

While functionality is paramount, industrial spaces can benefit from flooring options that also enhance the overall appearance of the environment with many color choices.

Variety of colors is also helpful in zoning demarcation for car park flooring and multi-function set-up.